WSZ - A series of sewage treatment equipment form A complete set of automatic alarm system, electric control system and equipment damage equipment reliability is good, so normally the need of personnel management, monthly quarterly maintenance and maintenance.

Technological process:

1. Description of wastewater treatment process:

Biofilm method is used in this project: hypoxia -- good oxygen (A/0) treatment process. A/O the anaerobic + aerobic biological contact oxidation process is A kind of mature biological treatment technology, has A high volume load, biological degradation speed, cover an area of an area small, infrastructure investment and low operation cost, can replace the original urban sewage treatment by ordinary active sludge method, especially suitable for medium and high concentration of industrial wastewater treatment, and province, covers an area of less investment, high processing efficiency. The process is mature and reliable by means of biological contact oxidation and precipitation. Precipitation sludge in equipment, due to the effect of dissolved oxygen in part of the sludge has been further oxidation decomposition, part of the gas stripping to settling tank, the system only regular in settling sludge pump in the tank. In the system, the main control equipment, such as the fan and the submersible pump, is fed into the PLC machine to achieve automatic work, so as to reduce the operation workload and reduce unnecessary human damage.

1.1 grid:

The discharged sewage is collected by the pipe network system and then enters the subsequent processing system after the coarse grille. The coarse grilles are mainly used to block the large floating objects in sewage, so as to ensure the normal operation of the structures and reduce the processing load effectively, so as to guarantee the long-term normal operation of the system.

1.2 sewage regulation pool:

It is used to adjust the water quantity and uniform water quality, so that the sewage can be more evenly distributed into the subsequent processing unit. Adjusting pool set pre aeration system, can improve the impact resistance of the whole system, and the reduction of wastewater in anaerobic condition of stench, at the same time can reduce the design of the subsequent processing unit scale, sewage pool submersible sewage pump is installed inside, to elevate sewage to the subsequent processing unit.

1.3 hypoxia pool:

An elastic filler is set up in a hypoxic pool to block small suspended solids in sewage and remove some of the organic matter. The denitrification and denitrification were obtained in the anoxic pool after the reflux, and the removal rate of ammonia nitrogen was increased. After anoxic treatment of sewage into aerobic biological treatment ponds.

1.4 contact oxidation pool:

Most of the raw sewage in the degradation of organic matter and purification, aerobic bacteria with packing as a carrier, use of organic matter in sewage for food, organic matter decomposition in the sewage into inorganic salts, purification so as to achieve purpose. The survival of aerobic bacteria must be sufficient oxygen, that is, sufficient dissolved oxygen in sewage to achieve the purpose of biochemical treatment. Aerobic pool is provided by the fan air, pool using new semi soft packing, the packing surface area than the big, long service life, easy hanging membrane, corrosion resistance, bottom using microporous aerator, make high dissolved oxygen transfer rate, at the same time there is light weight, not aging, not easy jam, long service life, etc.

Two parts in the contact oxidation pool:

Packing: this process adopts a new type of three-dimensional elastic packing, which has the advantages of large surface area, long service life, easy mounting film and corrosion resistance. Can have certain stiffness at the same time, the packing, the bubbles of sewage in multi-level cutting, increase the efficiency of dissolved oxygen (do), moreover between packing and packing is not easy to cluster, avoid the jam of oxidation pond.

Aerator, microporous aerator is applied in this process, the dissolved oxygen transfer rate is higher than other aerator, the biggest characteristic is not aging, light weight, long service life, and has the advantages of corrosion resistance, not easy jam.

1.5 sedimentation tank:

Sewage after dealing with the biological contact oxidation pool artesian water into the pond, and precipitation to further remove the fall off of biofilm and part of the organic and inorganic particles, settling basin is based on the principle of gravity, when sewage containing suspended solids flow from down to up, by gravity, will settle matter. After the settling pond, the water is clearer and more transparent. The secondary sedimentation tank is a vertical flow sedimentation tank, and sludge pump is used to carry the mud to the sludge digester regularly. The treated water after precipitation enters the follow-up processing equipment.

1.6 disinfection pool

Sewage after precipitation, virus and e. coli index is still at the end of the meet emissions standards, in order to eliminate viruses and e. coli, cast slice of disinfectant chlorine disinfection treatment, in the form of folded plate, relying on its own gravity, direct emissions near the municipal pipeline.

1.7 sludge digester:

The residual sludge discharged from the sedimentation tank is treated with aerobic digestion in the tank to reduce the volume of the sludge and improve the stability of the sludge. After aerobic digestion, the amount of sludge is less, and regular contact is made by the sanitation department to remove the external transport or the sludge dewatering. The supernatant was used to return to the regulating tank.

1.8 the fan:

It is used to contact oxidation pond gas supply, adjust pool pre-aeration and sludge digestion tank.

2. Electrical control instructions.

PLC fully automatic control of sewage treatment equipment from water inlet to outlet water. The specific control contents are as follows:

(1) the liquid level control device is set up in the sewage regulating tank, and the high liquid level automatically runs; Low level stop pump.

(2) the fan is operated alternately and continuously. The two fans can set the automatic switching interval according to the requirement.

(3) the sewage treatment station is recommended to use dual power supply. The main machine pumps are used alternately for each other, so as to ensure the normal operation.

(4) each kind of electrical equipment start-up, shut down and switch the linkage by programmable controller automatically according to the program, at the same time on the panel of the control cabinet is equipped with automatic, manual switch, switch to manual control when necessary.

(5) all kinds of electrical equipment are equipped with circuit short circuit and over-carrier device, and the indicator light is set to display the working status of each electrical equipment.

3. Equipment room and operation room.

The electric control cabinet shall be set in the ground building, and it is recommended to be disposed in the water treatment room next to the main structure of sewage treatment, so as to facilitate daily operation management and equipment maintenance.

4. Anti-corrosion measures

In the process of underground sewage treatment equipment, the material of the main equipment is steel structure, which is deeply anticorrosive. The inner and outer surfaces are treated with mechanical derusting, and the inner and outer surfaces are embalmed with epoxy coal tar. All connected pipes and fittings are made of PVC and ABS material, which can resist corrosion of acid, alkali and salt. Steel parts are anticorrosive with epoxy coal tar.

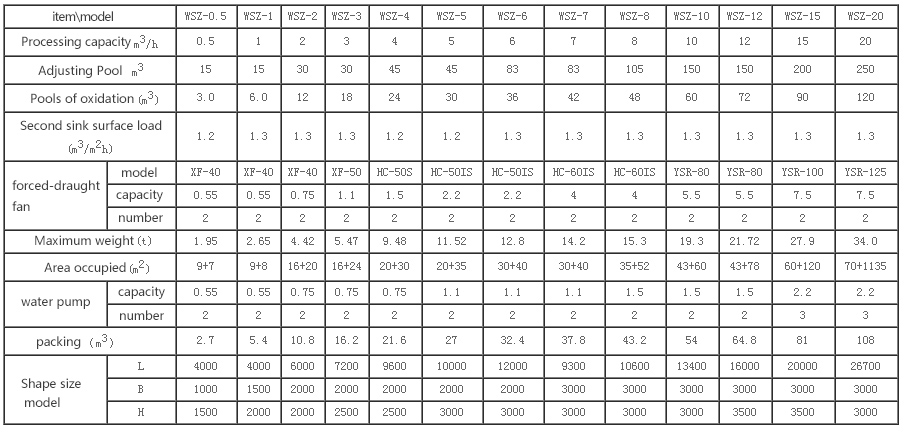

Technical parameters

Wsz-f equipment technical parameters table: